STEP 4 | Finalize your system configuration based on:

- Pump flow — E.g.: 17 liters/hour; 7 gallons/hour

- Chemicals used in the process — Determines the components materials

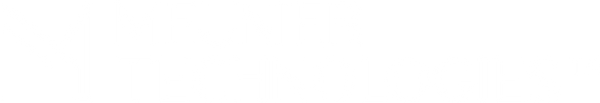

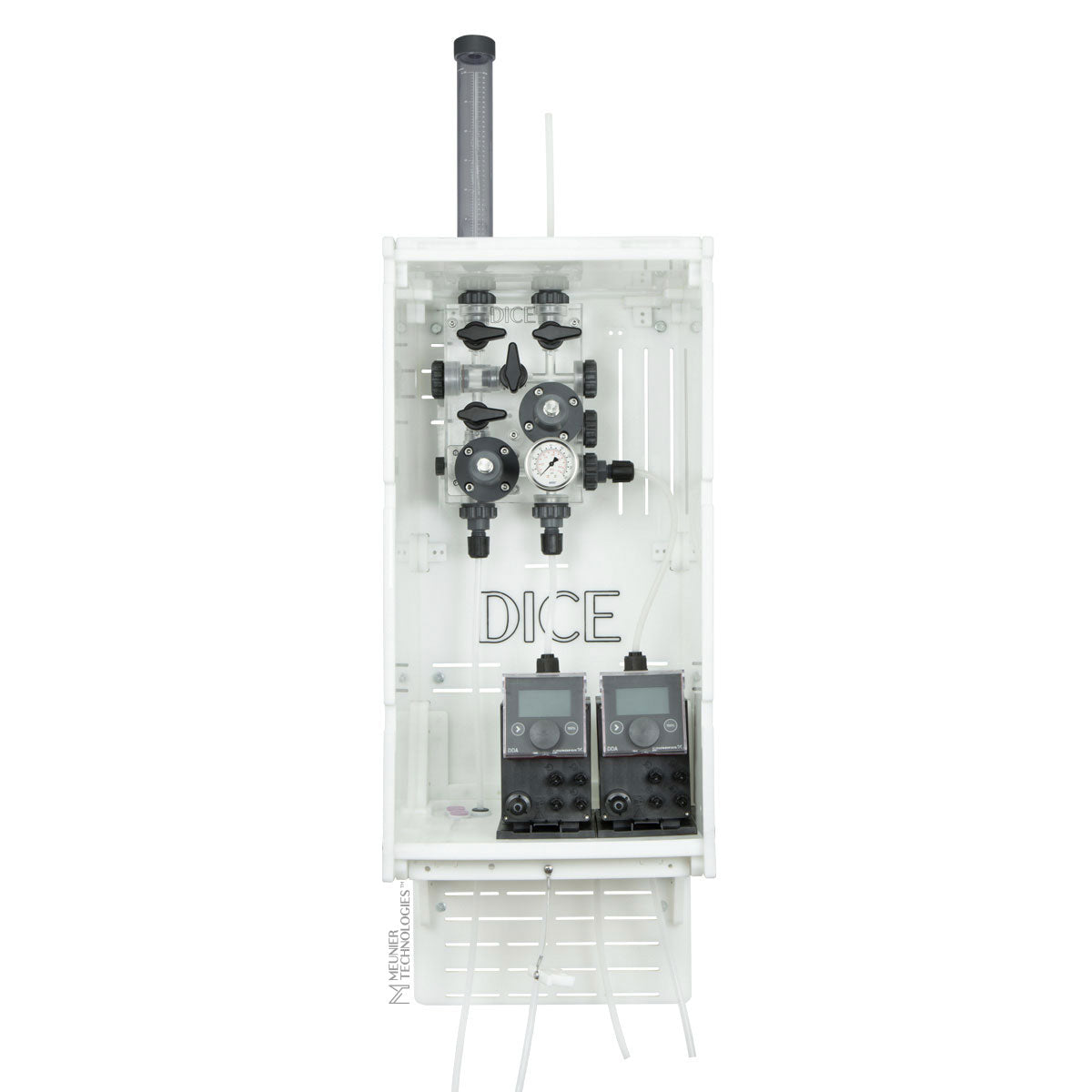

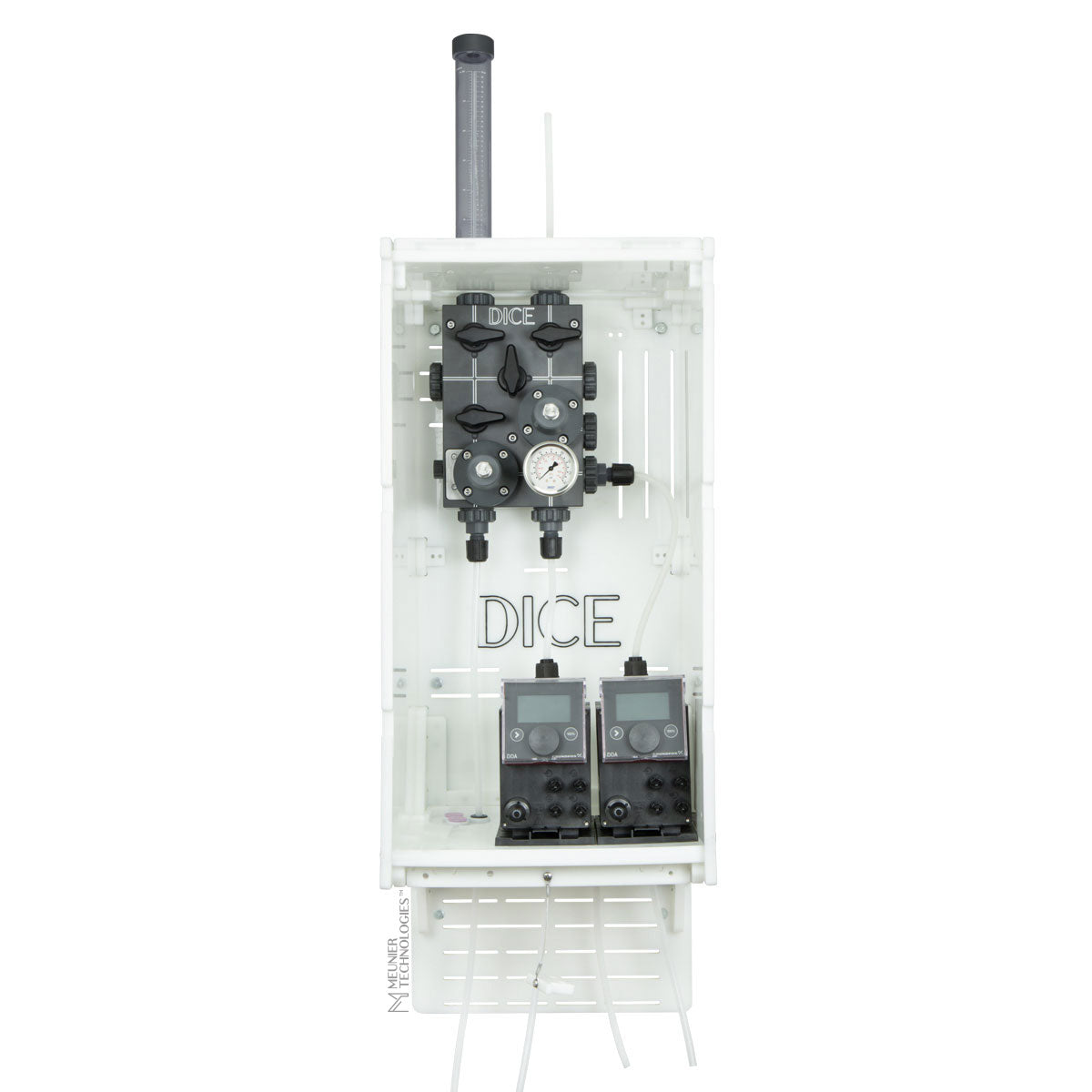

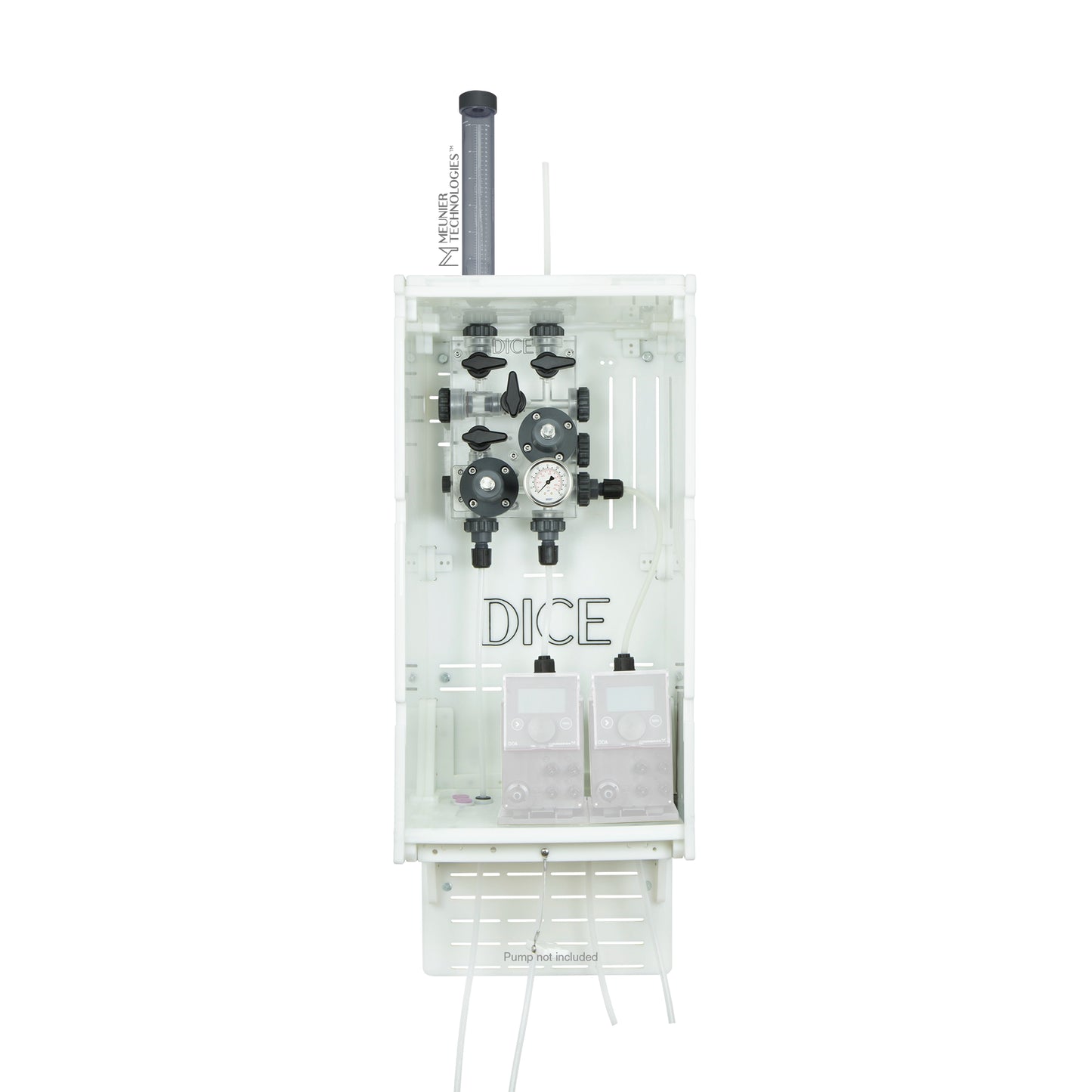

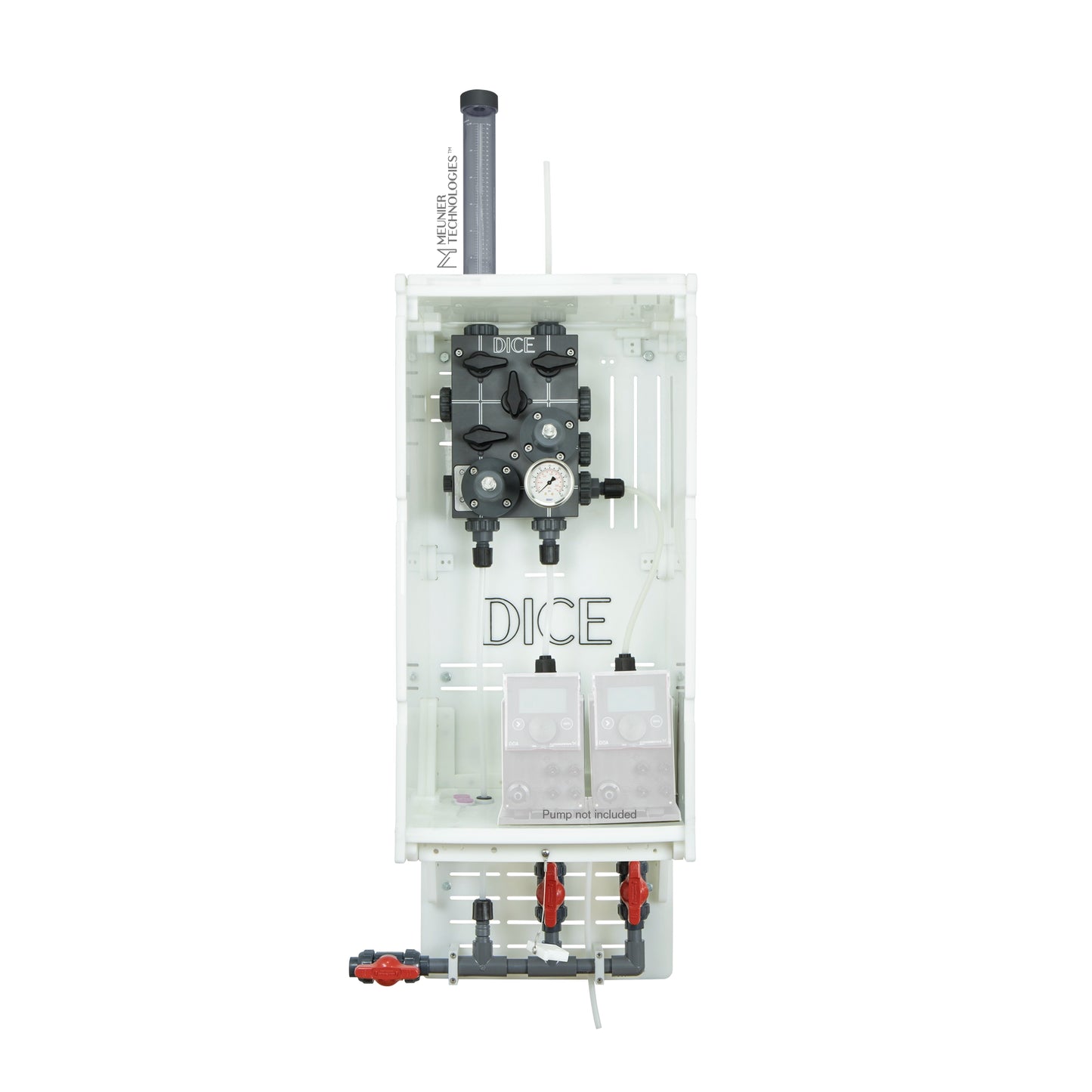

DICE™ System DM 1/2" - Wall Mount - Enclosure - Duplex

DICE™ System DM 1/2" - Wall Mount - Enclosure - Duplex

SKU:SYS4E-DDDA7.5-16-21MVII-1PP-NTN-NNN-N

Note: Refer to delivery section regarding taxes, tariffs, importation duties and minimum order value.

Couldn't load pickup availability

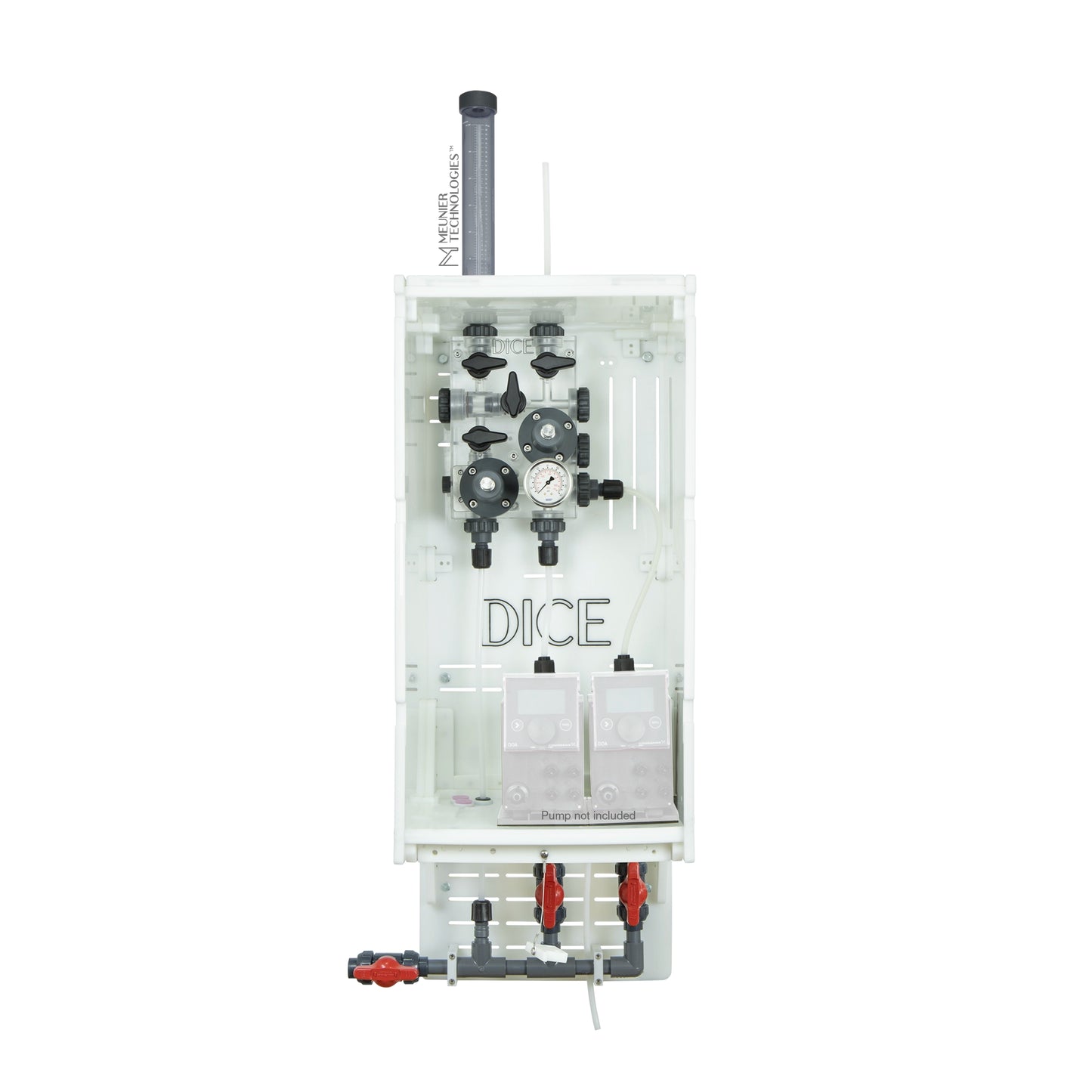

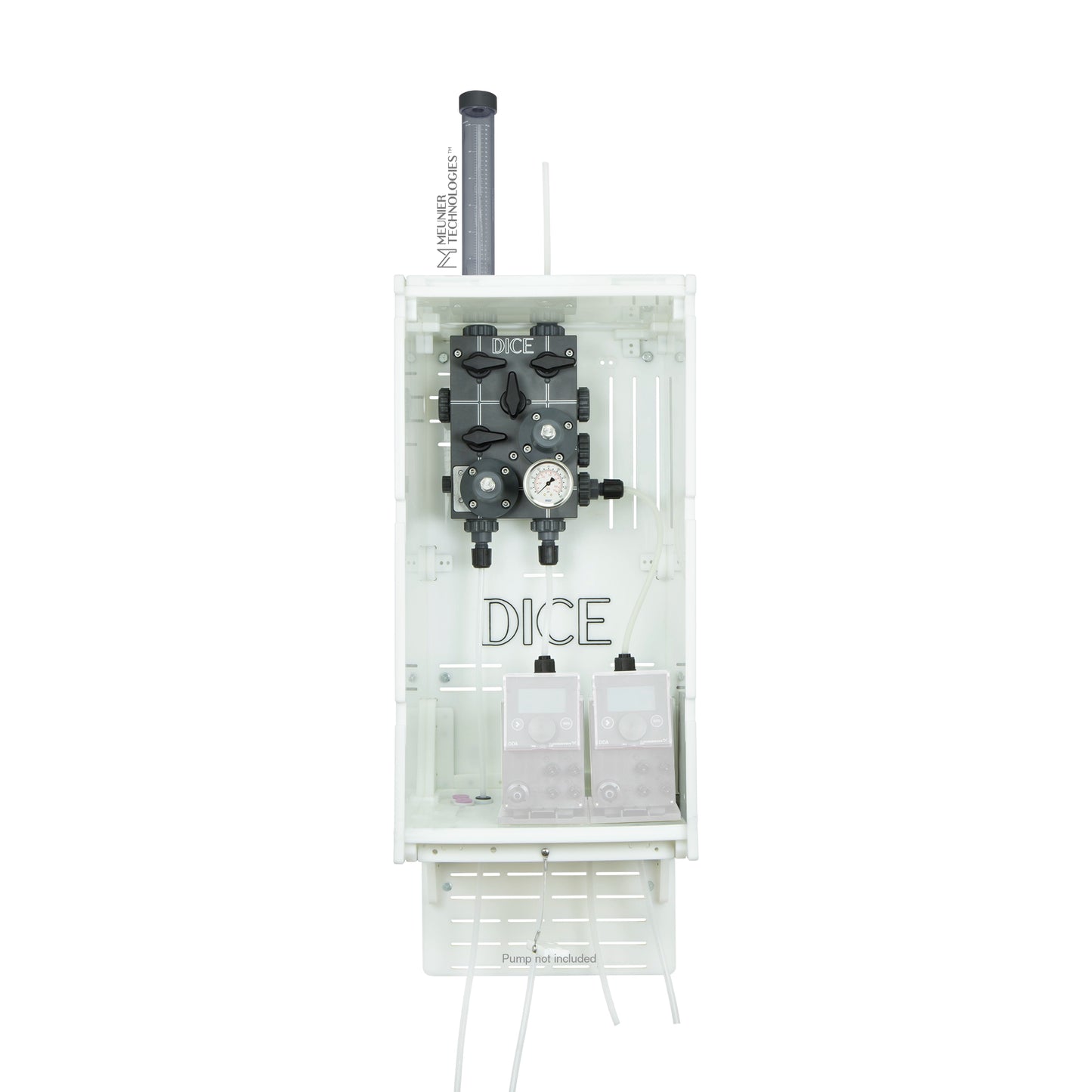

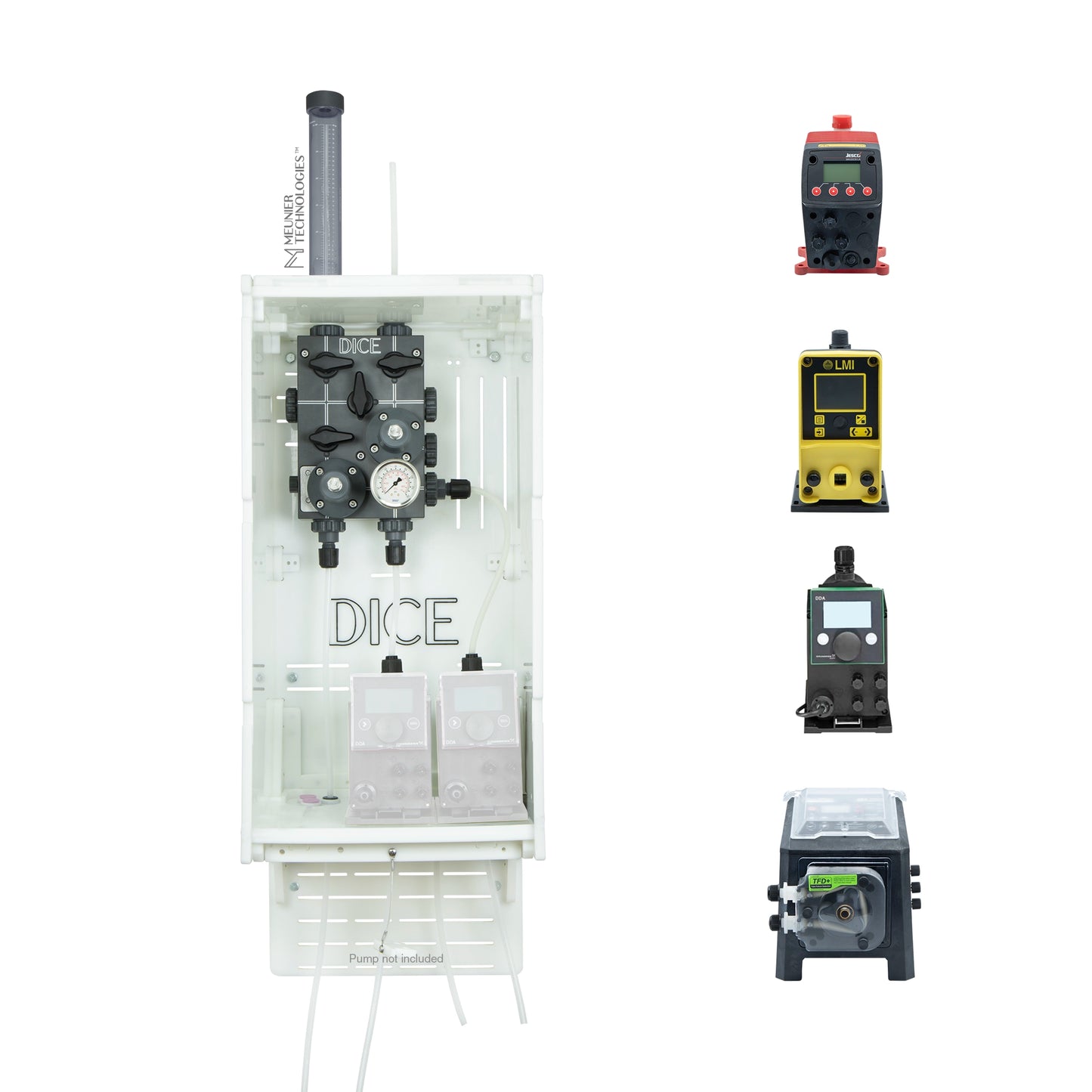

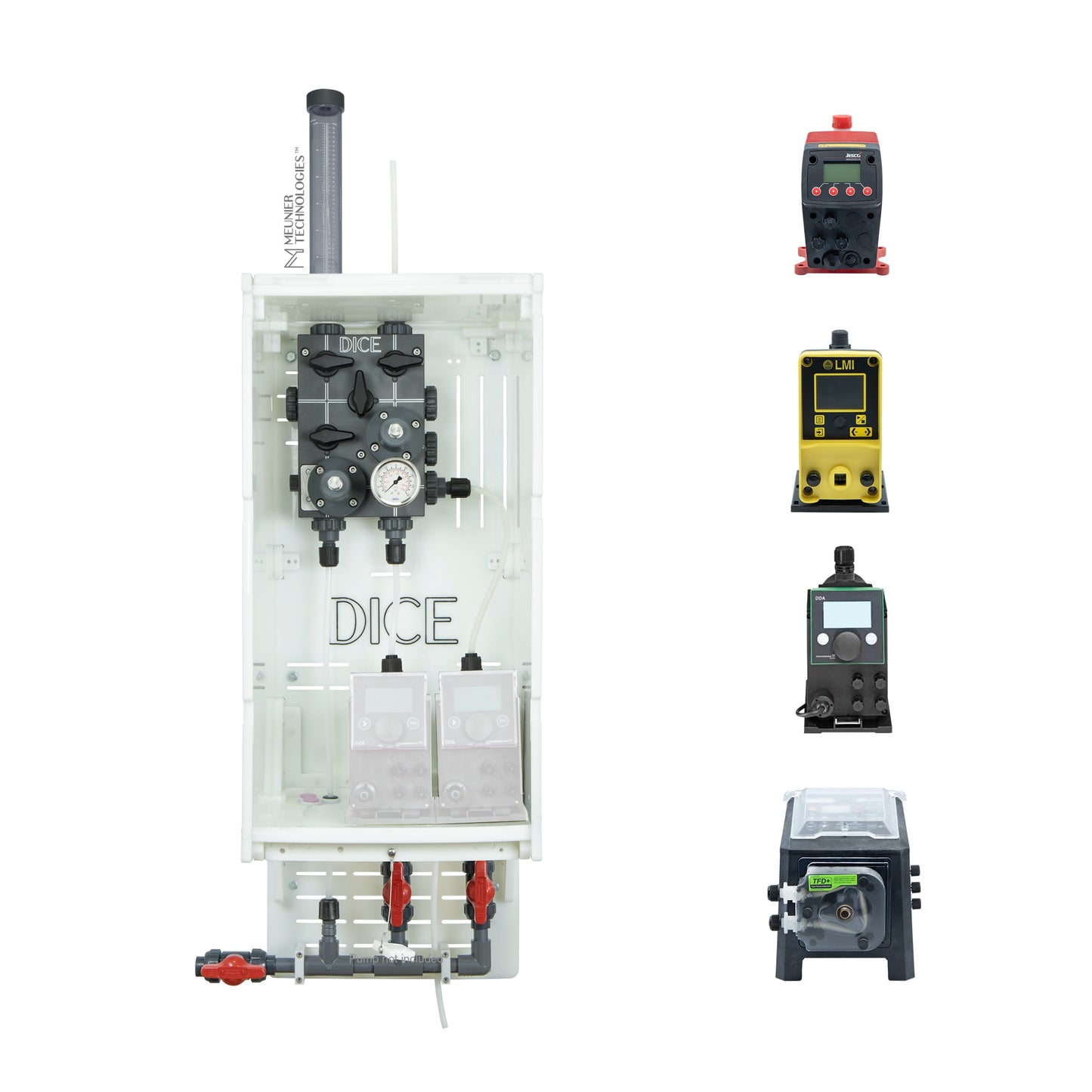

Images are for reference only. They do not represent all possible configurations and materials.

Share

Contact

Have a question? Feel free to write to us through this form and we will get back to you shortly. You may also contact us by phone: +1-450-413-1311.

DICE MODULE

1 DICE™ Dosing Module: DM 1/2" with the selected wetted parts material.

DICE PANEL

1 DICE™ Panel Wall Mount - Enclosure

Dosing pump

2 pumps

Grundfos DDA model AR

The pump head and gasket materials are in accordance with the selected DICE™ system materials

Refer to the pump and calibration column for the complete part number.

All pumps are equipped with ceramic ball check

The pump inlet and outlet are preconnected using the selected tubing

The pump is mounted on a Grundfos base plate

1.5m electrical power supply cord

No pump calibration is performed (available as an option)

No foot valve included; Refer to DICE™ parts to see our standard DICE™ foot valves available

No control cable included (option available on a RFQ basis)

We offer on a RFQ basis other types of Diaphragm and Peristaltic pumps such as Blue & White, LMI, Jesco, Watson Marlow, etc.

Calibration cylinder

The Calibration column material is in accordance with the selected DICE™ system materials

Refer to the pump and calibration column table for the exact calibration column volume and material

Piping/Tubing

Tubing/piping assembly - as per drawing (Refer to the correct page base on your selection – with or without a suction manifold)

No piping or tubing from the DICE™ injection port

When a suction manifold is selected, no piping or tubing is included upstream of the manifold inlet isolation ball valve

When no suction manifold is selected, 6 ft of tubing is included from both the pump inlet and the DICE™ module Drain

If the system is selected without pumps:

The system does not include the pumps but is equipped with the selected tubing to connect both your pump inlet and outlet. An extra length of 12in is supplied on both sides of the pumps allowing for the final length to be cut on site.

Control and wiring

No junction box (option available on a RFQ basis)

No wiring (1.5m electrical power supply cord included directly on the pump)

Assembly

The DICE™ System come pre assembled as per the selected DICE™ module, DICE™ panel and piping/tubing layout.

The DICE™ System materials are supplied in accordance to the selected materials for the DICE™ block, wetted parts, seals and tubing.

Approval:

Before any project execution, final drawing will be supplied by Meunier Technologies Inc. to be approved by the client.

FAT test

Consisting of operating the system at a maximum Pump or DICE™ pressure, inspecting for leaks and performing a 24hr hydrostatic test.

Specific hydrostatic test can be performed if required (additional charge may apply).

*This table should only serve as guidelines, they are suggestions based on third party chemical compatibility charts, refer to Meunier Technologies Inc. T&Cs.

DICE™ DS/DM: How to Install the DICE™ Chemical Dosing Modules DS and DM

DICE™ Panel: How to Assemble the DICE™ Panel

DICE™ System: How to Install the DICE™ DS & DM Module on DICE™ Panel

Lead time

- 3-4 weeks standard lead time (excluding pump lead time).

Shipping

Meunier Technologies's carrier

- 1-3 days for urgent requests

- 1 week standard shipping

Your own carrier

- Depends on your terms

Packaging

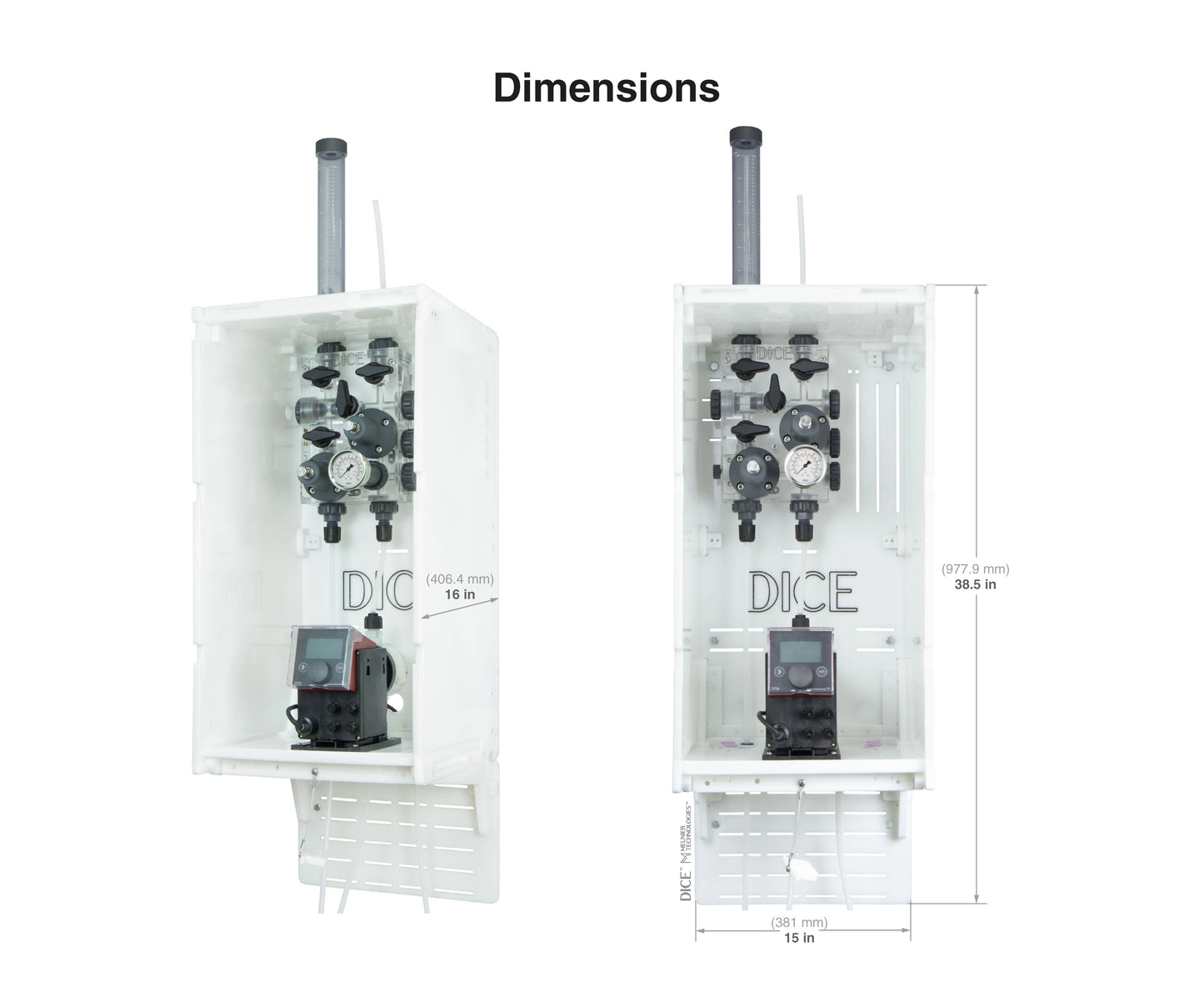

The DICE™ System will be package in a 16’’ X 16’’ X 48’’ cardboard box.

Price

This price does not include any shipping cost and importation cost; including but not limited to brokerage fees, taxes and tariffs. Meunier Technologies enforces a minimum order value of 500.00 $ USD. For smaller order, please contact us or our distributors.

DICE MODULE

1 DICE™ Dosing Module: DM 1/2" with the selected wetted parts material.

DICE PANEL

1 DICE™ Panel Wall Mount - Enclosure

Dosing pump

2 pumps

Grundfos DDA model AR

The pump head and gasket materials are in accordance with the selected DICE™ system materials

Refer to the pump and calibration column for the complete part number.

All pumps are equipped with ceramic ball check

The pump inlet and outlet are preconnected using the selected tubing

The pump is mounted on a Grundfos base plate

1.5m electrical power supply cord

No pump calibration is performed (available as an option)

No foot valve included; Refer to DICE™ parts to see our standard DICE™ foot valves available

No control cable included (option available on a RFQ basis)

We offer on a RFQ basis other types of Diaphragm and Peristaltic pumps such as Blue & White, LMI, Jesco, Watson Marlow, etc.

Calibration cylinder

The Calibration column material is in accordance with the selected DICE™ system materials

Refer to the pump and calibration column table for the exact calibration column volume and material

Piping/Tubing

Tubing/piping assembly - as per drawing (Refer to the correct page base on your selection – with or without a suction manifold)

No piping or tubing from the DICE™ injection port

When a suction manifold is selected, no piping or tubing is included upstream of the manifold inlet isolation ball valve

When no suction manifold is selected, 6 ft of tubing is included from both the pump inlet and the DICE™ module Drain

If the system is selected without pumps:

The system does not include the pumps but is equipped with the selected tubing to connect both your pump inlet and outlet. An extra length of 12in is supplied on both sides of the pumps allowing for the final length to be cut on site.

Control and wiring

No junction box (option available on a RFQ basis)

No wiring (1.5m electrical power supply cord included directly on the pump)

Assembly

The DICE™ System come pre assembled as per the selected DICE™ module, DICE™ panel and piping/tubing layout.

The DICE™ System materials are supplied in accordance to the selected materials for the DICE™ block, wetted parts, seals and tubing.

Approval:

Before any project execution, final drawing will be supplied by Meunier Technologies Inc. to be approved by the client.

FAT test

Consisting of operating the system at a maximum Pump or DICE™ pressure, inspecting for leaks and performing a 24hr hydrostatic test.

Specific hydrostatic test can be performed if required (additional charge may apply).

*This table should only serve as guidelines, they are suggestions based on third party chemical compatibility charts, refer to Meunier Technologies Inc. T&Cs.

Lead time

- 3-4 weeks standard lead time (excluding pump lead time).

Shipping

Meunier Technologies's carrier

- 1-3 days for urgent requests

- 1 week standard shipping

Your own carrier

- Depends on your terms

Packaging

The DICE™ System will be package in a 16’’ X 16’’ X 48’’ cardboard box.

Price

This price does not include any shipping cost and importation cost; including but not limited to brokerage fees, taxes and tariffs. Meunier Technologies enforces a minimum order value of 500.00 $ USD. For smaller order, please contact us or our distributors.